Insulation helps reduce energy costs for industrial buildings. It also protects equipment from extreme heat and cold, extending the life of capital investments.

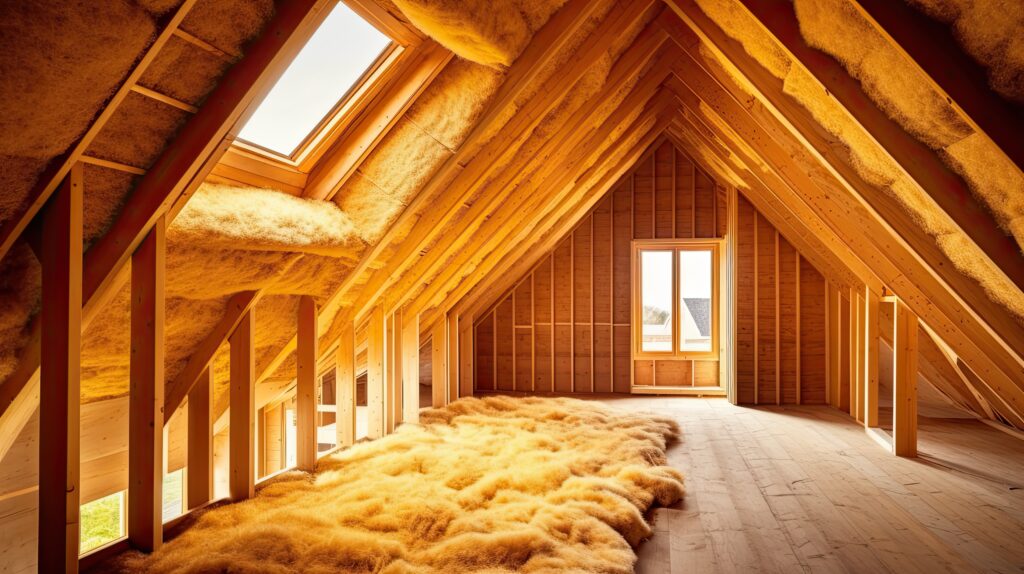

Industrial insulation works via the same principles as the fiberglass batting in your attic, but it is much more flexible and comes in many different forms. Some major forms include:

1. Reduced Energy Costs

Approximately 25% to 30% of energy is wasted due to improper insulation. Incorporating energy-efficient insulation practices can help you drastically reduce your business’s energy costs. The upfront cost of incorporating new insulation may seem daunting at first, but it doesn’t take long for the initial investment to pay off in terms of savings on your energy bills.

Insulation minimizes heat transfer, reducing the load on heating and cooling systems. This results in reduced energy consumption, lower utility bills, and substantial savings on your business’s energy costs.

In addition to lowering your energy costs, insulation can also help you comply with strict energy-efficiency regulations. Many governments worldwide have implemented energy-efficiency standards, making it crucial that you adhere to these guidelines to avoid costly penalties or fines.

There are a variety of options for implementing energy-efficient insulation in your industrial space. Structural insulated panels (SIPs) are prefabricated insulated building elements that can be used in the walls, floors, ceilings, and roofs of your industrial space. This type of insulation is extremely versatile and offers superior insulating performance compared to traditional construction methods such as stud or stick frame building.

Spray foam insulation is another insulation option that offers exceptional air sealing and thermal performance. It expands to fill even the smallest gaps and nooks, leaving no room for heat or cold to escape. In addition, it’s made from recycled materials like newspapers, which cuts down on landfill waste.

Other types of insulation include foam board, cellulose, fiberglass, and reflective insulation. Foam board and cellulose offer excellent thermal efficiency, while fiberglass is an affordable option that’s easy to install. Reflective insulation reflects radiant heat away, which makes it ideal for areas that receive scorching temperatures.

2. Increased Productivity

Insulation isn’t only an energy-saving solution, it also increases productivity on the job. Pipe insulation, for example, prevents iron, copper, CPVC, and PVC pipes from being warmed or cooled by the environment outside, making it easier for workers to work on them without getting too hot or cold.

Unlike the fiberglass batting in your attic, industrial insulation is more versatile and comes in many varieties. This is because it is designed to solve specific problems in different environments. For example, the insulative layers in astronaut suits help prevent them from freezing at -250F or burning up at +450F.

To illustrate this point, have students conduct an experiment with multiple materials that will act as an insulator. They should use a timer to measure the amount of time it takes for an ice cube to melt in each of the beakers. The material with the longest melting time is considered the best insulator.

3. Reduced Maintenance Costs

Insulation saves energy, which means it helps businesses keep more of their hard-earned dollars. It also protects equipment from harsh environments, like extreme temperatures and moisture. This reduces maintenance costs and extends the lifespan of equipment.

At its core, industrial insulation works much like the batting in your home’s attic, but it is more versatile and comes in many varieties. It prevents the transfer of heat from the interior to the exterior, which improves a building’s overall efficiency, safety, and durability while helping to maintain indoor environmental quality (IEQ).

There are many different types of insulation materials that are suitable for varying environments, but some stand out above the rest. Rock wool pipe insulation is a good choice for hot-tempered environments that reach up to 1200 degrees Fahrenheit. It’s made of tightly woven fibers that create a barrier between a pipe’s contents and the outside environment, stopping corrosion, heat loss, condensation, and exterior damage — all vital to a building’s safety and durability. It also helps to reduce energy consumption and lower greenhouse gas emissions, making it an eco-friendly solution that aligns with consumers’ demand for sustainability practices.

4. Reduced Noise

Insulation can help with more than just reducing energy costs; it also has the ability to reduce noise. This can be a benefit to your employees, especially if you have loud machinery, or for your neighbors who live near your building. By installing soundproof insulation, it can prevent the transfer of sounds and make your space a more pleasant environment.

Noise pollution is a common problem in many industrial environments. However, it is easily avoided by using the right types of insulation. By incorporating acoustic insulation into the walls and roof systems of your industrial building, you can significantly decrease exterior noise levels.

There are a few different types of sound reducing insulation available, including Roxul’s Safe ‘n’ Sound. This insulation is designed specifically for acoustic applications, and offers excellent fire resistance and thermal properties as well. Another option is cotton insulation, which is made from recycled denim and cotton fibers and is both eco-friendly and fire resistant.

The type of insulation that you choose for your industrial building will depend on the specific application and your budget. Choosing an insulation with a higher STC (sound transmission class) rating will help to keep noise levels down and will be more effective at reducing both airborne and impact noise.

In addition to reducing noise, industrial insulation can also help to keep pipes from freezing in cold environments. This can be an important feature for factories and other industrial settings where water pipes are in use. This can prevent unwanted bursting or leaks that could otherwise lead to expensive repairs and replacements. By using insulation that is specifically designed for pipe temperatures, you can avoid this issue altogether.

5. Increased Safety

Insulation is an unsung hero of the industrial sector. It keeps machinery and equipment safe from the elements while saving energy costs, increasing productivity, and reducing maintenance. Insulation can protect pipes from freezing temperatures, prevent heat loss, and even regulate noise levels.

Pipe insulation, such as Polyguard products, is critical to a building’s efficiency, safety, durability, and indoor environmental quality (IEQ). It stops pipe corrosion, heat loss, condensation, exterior damage, and more. It also reduces the risk of worker injuries due to cold temperatures and prevents workers from getting burns on hot-tempered pipes.

Other types of insulation like tank insulation are made to protect tanks, containers, and vessels from varying environments or climates. It can be designed to address both conductive and radiant heat transfer, keeping the contents of the tank at an optimal temperature. This is also important for maintaining liquid and gas consistency. Similarly, heat tracing is used to keep pipes warm in harsh or cold environments. This prevents ice from forming and slowing down production or causing other costly problems. This also prevents heated or cooled air from escaping and consuming more energy.